Silverthorne Engineering has over 50 years experience in the design and manufacture of tooling for Tube Rolling and Section Forming Mills.

It is this, coupled with a highly skilled workforce and our continual investment in new plant and production techniques including investment in the latest CNC machinery, CadCam and Design software, which ensures the highest quality product for which the company has become known for.

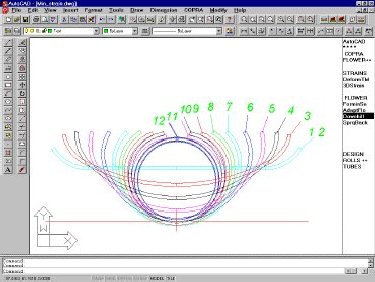

We have full design capability and can provide our customers with a complete turnkey production process with the use of COPRA design and AutoCAD drafting software which links seamlessly with our CadCam software.

Our extensive CNC machining capacity – up to 1200mm in diameter – allows us to produce tooling to suit mills of all sizes. We are able to manufacture everything from leveller entry rolls through forming, sizing, turks head and shaping rolls, to straightening rolls and ancillary mill equipment.

Quality

We pride ourselves on our technical expertise and experience and our team are on hand to assist you with any design requirement. The various conditions in which rolls operate mean that materials and heat treatments need to be considered for each project. Contact us today to discuss your specific requirements.

Refurbishment

Silverthorne Engineering also offers an efficient refurbishment service. Where mill flexibility allows, rolls can be re-profiled in order to maintain tube size and/or shape. Contact us today and we can advise on the best approach to refurbishing your mill rolls.

Using only the highest quality materials from reputable suppliers and recognised heat treatment companies ensures that the finished product is of superior quality.

Manufacturing Range:

- Diameter Up to 47 inches / 1200mm

- Length Up to 118 inches / 3000mm